Published On Jun 9, 2021

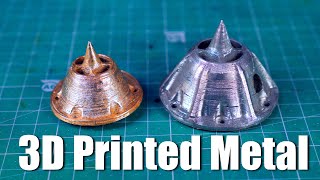

In this episode of our “AM: Why the Failure?” video series, Penn State professor of additive manufacturing (AM) Tim Simpson and I discuss a piston crown made through laser powder bed fusion (LPBF). Because of the way solving one problem with this part’s build led to another problem that needed to be solved, the iterative path to success makes this application perhaps the most representative of process development in AM of any episode so far.

Guesses by audience members in social media rightly identified first the support structure design and then the overall design of the build layout itself as culprits in build failure. The latter point proved key: In LPBF, Simpson notes, the parts on the build plate affect all the other parts in the same build. Success ultimately involved changing what additional parts shared the build with the crown part intended.

This episode brought to you by Verisurf. https://www.verisurf.com/

Related resources:

- LinkedIn audience discussions about this part (3 threads for 3 different phases of the build):

/ timothy-william-simpson_additivemanufactur...

/ timothy-william-simpson_amwtf-dfam-additiv...

/ timothy-william-simpson_amwtf-pbf-additive...

- Introduction to powder bed fusion: https://www.additivemanufacturing.med...

- Challenges of metal AM: https://www.additivemanufacturing.med...

- Metal AM successes and technology: https://www.additivemanufacturing.med...

Subscribe to THE BUILDUP, Additive Manufacturing Media's newsletter on 3D printing for industrial production: https://gbm.media/JoinTheBuildup